ASTM A213, A269 904L simbi isina tsvina yakamonerwa tubing muChina

Alloy 904L isimbi isina kugadzikana, yakakwira alloy austenitic Stainless simbi ine yakaderera kabhoni.Inoshandiswa zvakanyanya mumashandisirwo apo iyo corrosion properties yeTP316/L uye TP317/L haina kukwana.Iyo alloy inopawo yakanakisa kuumbwa, weldability, uye kuoma.Kuwedzerwa kwemhangura kunopa alloy 904L corrosion resistant properties iyo yakakwirira kune yakajairwa chrome nickel simbi isina tsvina.Mienzaniso inosanganisira kuramba sulfuric, phosphoric, uye acetic acids.

Size Range

| Kunze Diameter (OD) | Kukora Kwemadziro |

| .250”–1.000” | .035″–.065″ |

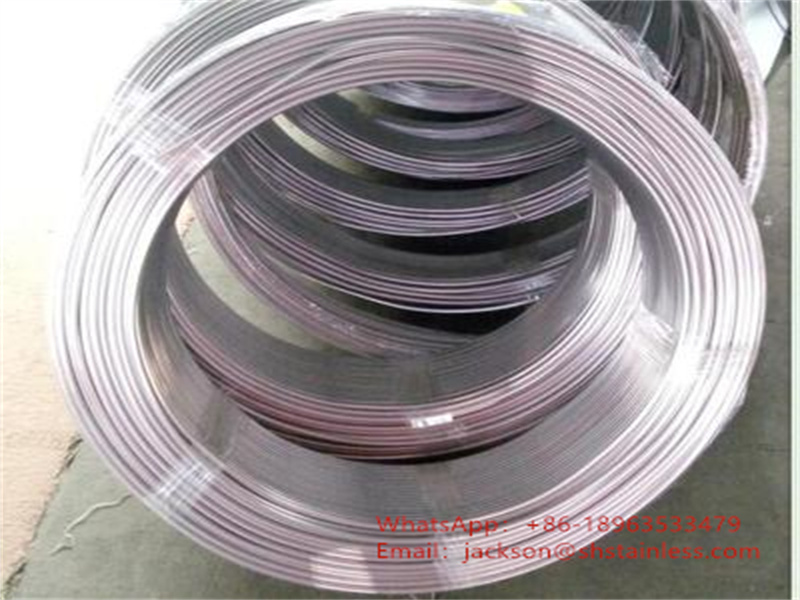

Kutonhora kwapera uye kupenya annealed chubhu.

Kemikari Zvinodiwa

Alloy 904L (UNS N08904)

Kuumbwa %

| C Carbon | Mn Manganese | P Phosphorus | S Sulfur | Si Silicon | Cr Chromium | Ni Nickel | Mo Molybdenum | N Nitrogen | Cu Mhangura |

| 0.020 max | 2.00 max | 0.040 max | 0.030 max | 1.00 max | 19.0–23.0 | 23.0–28.0 | 4.0–5.0 | 0.10 max | 1.00–2.00 |

Dimensional Tolerances

| OD | OD Kushivirira | Kushivirira Kwemadziro |

| ≤ .500″ | ± .005” | ± 15% |

| 0.500”–1.500” | ± .005” | ± 10% |

Mechanical Properties

| Goho Simba: | 31 ksi min |

| Tensile Simba: | 71 ksi min |

| Kurebesa (min 2″): | 35% |

| Kuoma (Rockwell B Chikero): | 90 HRB max |

Fabrication

Alloy 904L isiri-magnetic mumamiriro ese uye ine yakanakisa formability uye weldability.Iyo austenitic chimiro chinopawo iyi giredhi kusimba kwakanyanya, kunyangwe pasi kusvika kune cryogenic tembiricha.

Indasitiri Applications

Chemical Process

Yayo yakakwira chromium uye nickel yemukati, pamwe nekuwedzera kwe molybdenum nemhangura, inobatsira alloy 904L kumira kune sulfuric, phosphoric uye acetic acid.Izvi zvinonyanya kukosha mukugadzirwa kweasidhi nefetereza.

Nyora meseji yako pano ugotitumira